Its existing system from a German vendor was upgraded in just six days without stoppages to operations.

The chemicals industry is entrenched in not just the production of petrochemicals and polymers, but also important pharmaceuticals and medical industries, including being part of the supply chain of personal protective equipment, masks, sanitizers, and industrial hygiene and cleaning.

In the Asia Pacific region (APAC), the chemicals industry contributes more than 45% of the global chemical manufacturing and close to 70% of global jobs in the chemical industry.

Such critical infrastructures are being digitally transformed to meet the current pandemic demands, but less talked about are the safety and cybersecurity aspects. But one chemical giant in China has managed to modernize their industry safety systems in just six days, with provisions for both real-time safety and cybersecurity baked into the system.

Six days of DX with minimal downtime

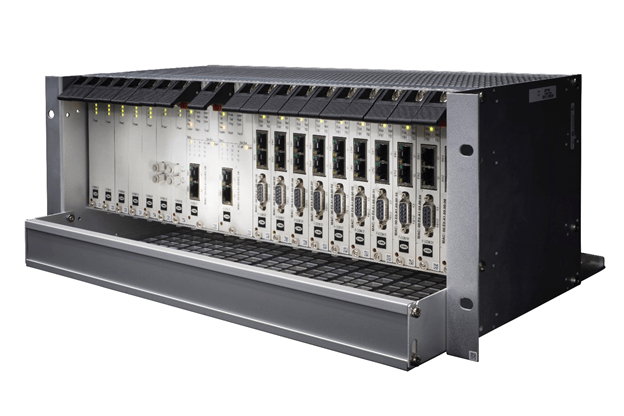

Ningbo ZRCC Lyondell Chemical Co., Ltd. (Ningbo ZRCC) has announced that it successfully upgraded its safety instrumented systems (SIS) in just six days without downtime, and it is the first in China to use the leading-edge solution for advanced industrial safety and cybersecurity features.

The project actually kicked off in early 2019, where the firm’s expanded needs in sewage treatment and future-proofing necessitating SIS upgrading and additional safety interlocks at its waste alkali incinerator. To fulfill the security element, the upgraded system must be able to maintain secure data communication with the original system.

Since downtime is detrimental to their mission-critical plant, Ningbo ZRCC made it mandatory for their supplier, German industrial smart-safety vendor HIMA, to ensure that the transition would be seamless, fast, and safe.

In June 2019, HIMA tested everything from hardware replacement to communication and logic—all in just six days on site.

Through the German firm’s modular technologies, Ningbo ZRCC was able to modernize their installation in a stepwise manner with minimal disruptions, using smaller maintenance outages of single units, while keeping the rest of the installation up and running.

Digitalization with safety in check

The chemical plant now has a safety network in place, where multiple controllers can act in a synchronized fashion when it comes to safety responses to critical situations. The upgraded installation uses Safe Ethernet technology that provides TÜV-approved security, allowing the running of technologies developed during 20 years to run concurrently and seamlessly.

According to Ningbo ZRCC’s engineering spokesperson: “Thanks to the elegantly simple and speedy upgrade, we can leverage the most advanced safety technology to ensure the safety of our plant within a limited time and budget. After the upgrade, we realized a tremendous upgrade in operating speed, especially with the upgraded system’s use of the engineering management platform that provides us with comprehensive data overview, ease of operation, and convenience.”

HIMA’s spokesperson Peter Sieber noted: “We at HIMA understand what mission-critical operations require, and we supported their challenging plan to do a stepwise modernization of their (existing HIMA) installation.” This was possible, Siber said, because of the firm’s product strategy combines long-lasting product lifecycles, full compatibility of products from different generations, and a comprehensive service portfolio.